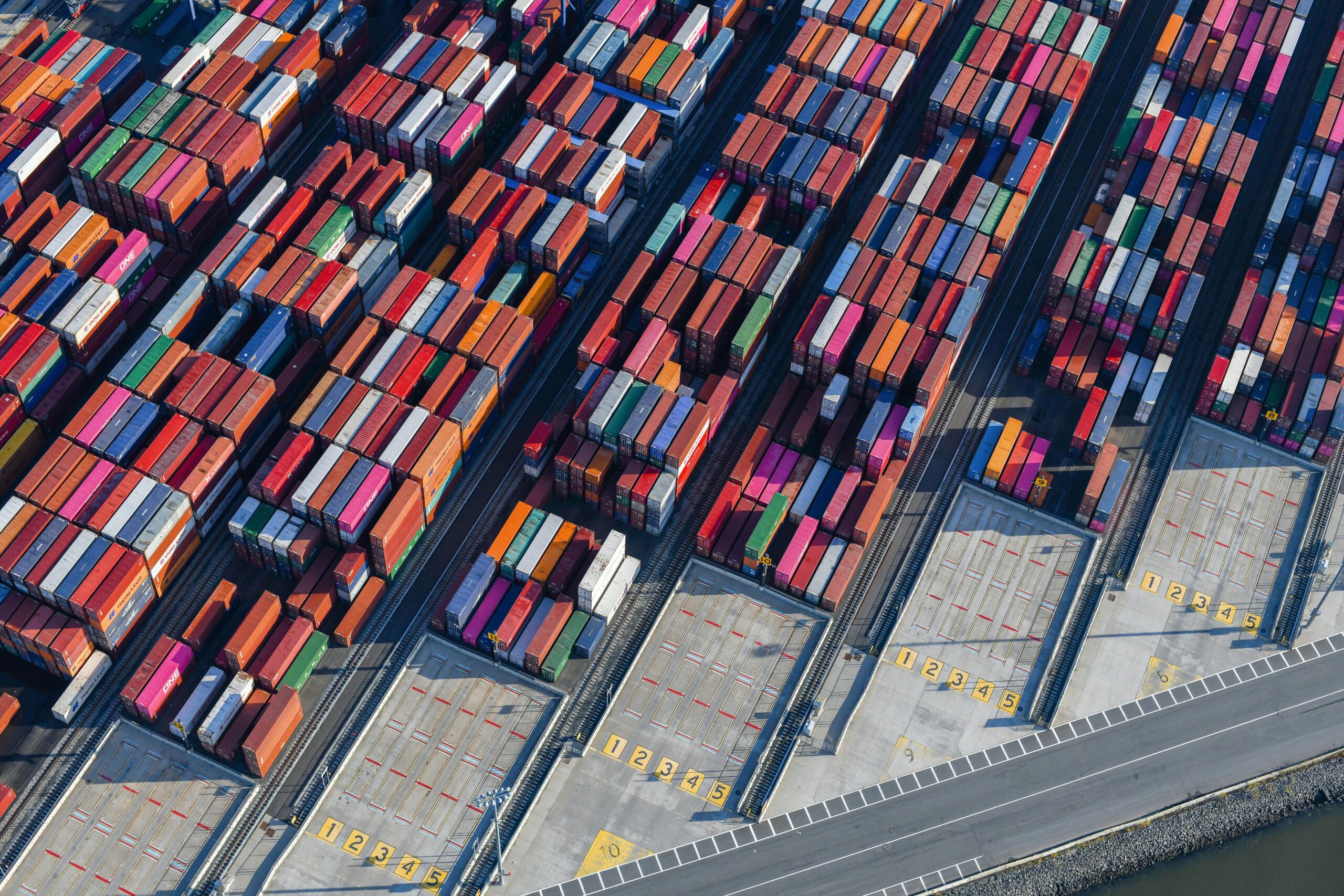

In today’s fast-paced business environment, the supply chain is a complex, interconnected network that must navigate constant disruptions while striving for greater efficiency. Artificial Intelligence (AI) has emerged as a transformative force, fundamentally changing how organizations plan, source, manufacture, and deliver goods and services. Far from being a distant concept, AI actively shapes intelligent and resilient supply chain operations in real time.

Let’s delve into ten significant ways AI is enhancing supply chain management:

1. Advanced Demand Forecasting and Planning

Traditional forecasting methods often falter in the face of volatility and unexpected disruptions. AI-driven machine learning and advanced analytics can analyze extensive datasets—including sales history, market trends, social media sentiment, and weather patterns—to produce highly accurate demand forecasts. This enhanced predictability improves inventory management, reduces stockouts, and optimizes production schedules.

2. Proactive Supply Chain Risk Management

Global supply chains are vulnerable to various risks, such as natural disasters, geopolitical tensions, and economic shifts. AI can identify, assess, and mitigate these risks in real time by analyzing diverse data streams from news outlets, logistics reports, and weather forecasts. Predictive analytics empowers businesses to anticipate disruptions and proactively adjust sourcing strategies, transportation routes, and inventory levels, ensuring continuity of operations.

3. Optimized Sourcing and Procurement

AI-powered procurement tools streamline the supplier selection process by evaluating performance metrics, financial stability, and ethical considerations. Automated procurement systems can generate purchase orders, negotiate contracts, and enhance supplier relationships, leading to increased efficiency and cost savings.

4. Smart Warehouse Management

As critical hubs in the supply chain, warehouses benefit significantly from AI integration. AI-enhanced Warehouse Management Systems (WMS) optimize storage locations, guide personnel, and improve labor and equipment utilization. Additionally, AI-driven robotics and Automated Guided Vehicles (AGVs) expedite the picking, packing, and movement of goods, reducing human error and increasing throughput.

5. Predictive Maintenance for Equipment and Assets

Unforeseen equipment failures can disrupt supply chain operations and incur significant costs. AI-driven predictive maintenance leverages IoT sensor data to identify patterns and anomalies that signal potential shortcomings. This proactive approach allows for timely maintenance scheduling, minimizing disruptions and extending the lifespan of critical assets. Digital twin technology further enhances asset performance monitoring and maintenance strategies.

6. Enhanced Transportation and Logistics

AI revolutionizes transportation management by optimizing routing, load planning, and carrier selection. AI-driven Transportation Management Systems (TMS) analyze real-time traffic conditions, weather data, and carrier performance to predict delays and recommend alternative routes. IoT-enabled real-time tracking enhances visibility, allowing proactive adjustments to ensure timely deliveries.

7. AI-Driven Quality Control

Maintaining product quality throughout the supply chain is essential for minimizing waste and ensuring customer satisfaction. AI-powered vision systems and machine learning algorithms can swiftly inspect products for defects more accurately than manual inspections. This leads to improved quality control, fewer returns, and a consistent product standard.

8. Personalized Customer Experience

AI enhances Customer Relationship Management (CRM) by analyzing customer behaviors, preferences, and purchase history. Businesses can utilize AI-powered analytics to segment customers, deliver personalized marketing campaigns, provide tailored product recommendations, and offer proactive customer support, fostering stronger customer loyalty.

9. Supplier Relationship Management (SRM) Enhancement

Robust supplier relationships are vital for supply chain resilience. AI-powered SRM systems assess supplier performance, identify potential risks, and facilitate data-driven collaboration. This enables businesses to forge stronger partnerships and refine their sourcing strategies, enhancing overall efficiency and reliability.

10. Optimized Reverse Logistics

Managing returns, repairs, and end-of-life product disposal is increasingly complex. AI optimizes reverse logistics by predicting return volumes, determining the most cost-effective disposition methods (repair, remanufacture, recycle, or dispose), and optimizing reverse transportation routes. This not only improves efficiency but also supports sustainability initiatives.

Conclusion: The Future of AI in Supply Chain Management

The pressing question is no longer whether businesses should integrate AI into their supply chains but rather how extensively they should harness its capabilities. As AI continues to evolve, its influence on supply chain efficiency, resilience, and customer satisfaction will only intensify. The intelligent supply chain is not merely a trend but the cornerstone of future business competitiveness in an ever-changing global market.

By embracing AI, organizations can navigate the complexities of modern supply chains and position themselves for sustained success in the future.